Supply chain is a decisive factor in getting ahead of your competitors, and hence, measuring its performance becomes necessary. If you are someone trying to gain a competitive advantage through leveraging your supply chain, then you must have come across the term DIFOT.

DIFOT is an abbreviation of ‘Delivered In Full, On Time’, which measures the number of complete orders that were delivered on time. There’s much more to discuss about DIFOT, and by the end of this guide, you will be able to use it as a strategic tool.

Why DIFOT Matters for Your Supply Chain

In this age of lightning-fast deliveries, DIFOT becomes an important metric to ensure your supply chain aligns with industry standards. A DIFOT report can be used to evaluate and track the performance of your suppliers.

DIFOT is an advanced KPI that showcases a firm’s success in fulfilling orders in the right quantity within the given time frame. It surpasses other alternatives like Shipped On Time (SOT) and On Time Delivery (OTD).

DIFOT KPI can even be utilised in cross-border shipping to develop a strong global network. In order to better understand what DIFOT is in the supply chain, it is essential to understand the meaning of DIFOT.

What “Delivery In Full” Really Means

‘Delivered in Full’ refers to the order being delivered in full quantity. Even if one quantity is less, then it will not be considered as ‘Delivered in Full’. The customer should receive and accept the delivery for the order to be completed.

What “On Time” Delivery Entails

The second half of the metric, ‘On Time’, indicates that the delivery is completed on time. The order should reach the customer on or before the estimated delivery time, to be considered ‘On Time’.

Together, they combine two key aspects of shipment deliveries to create a powerful tool. DIFOT is represented as a percentage, and the higher the rate, the better the performance of your supply chain.

Now you know what DIFOT means, but how is it calculated?

DIFOT Formula & Calculation Example

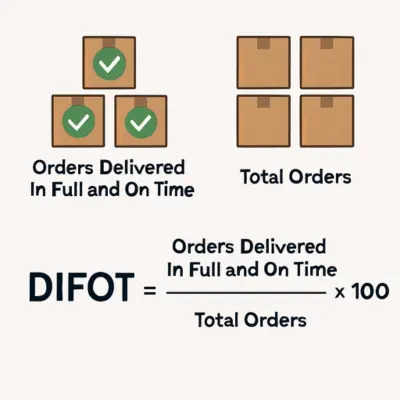

DIFOT Formula

The calculation of DIFOT is straightforward. It is represented as the percentage of orders that are delivered in full and on time with respect to the total number of orders.

DIFOT Calculation

Step-by-Step Calculation Example

For example, a firm completes 48 orders in full, and among them, 45 were on time out of 50 orders. The DIFOT can be calculated as follows.

- Step 1: Calculate the number of orders that are completed in full. Orders that are not delivered or partially completed should be discarded. Here it is 48.

- Step 2: Analyse the orders completed in full and select only the ones that are delivered on time. Identify the number of these orders, and we get 45 orders.

- Step 3: Estimate the total number of orders received by the firm in that particular window. The total includes orders that are not completed, partially completed, and fully completed. Total orders in this case are 50 orders.

- Step 4: With the number of orders delivered in full and on time and the total number of orders, calculate the DIFOT with the formula given above. For the above example, the DIFOT score is 90%.

Similarly, DIFOT can be calculated for any system if the necessary data is provided. And based on this information, the DIFOT report will be created.

You must be thinking, What is a DIFOT report?

DIFOT Reporting: How to Track & Visualize Your Performance

Tools and Dashboards

With DIFOT reporting, firms can track and monitor the performance of the supply chain and use the DIFOT scores to create value. Multiple tools are available that automate the reporting process and provide useful insights.

- Excel or Sheets: This is the simplest tool to use for reporting. It is easy to use and can be learned easily by anyone. Excel and Sheets share most of the functions, and you can choose either based on your convenience.

- Power BI: This tool from Microsoft has changed the dynamics of reporting by bringing visualisation to the forefront. Visualisations can be easily understood by any person with basic knowledge, making the job easier for reporting managers.

- Warehouse Management Systems (WMS): While Excel and Power BI can be adopted by small to medium networks, you will need a WMS to tackle a bigger supply chain. Such systems provide most of the functions of tools like Excel and Power BI at a much larger scale.

Sample Dashboard for DIFOT

Common Challenges That Impact DIFOT

- Stock management: Delivering the order in full is necessary for DIFOT. Sometimes, failure in delivery or partial delivery happens because of the unavailability of stocks. This issue is caused by improper stock management.

- Demand Forecasting: This is an extension of the stock management challenge. Failure in demand forecasting leads to stocks running out or excess stocks being stored.

- Order fulfillment delays: Several bottlenecks can occur in the order fulfillment phase, such as slow confirmation times or inefficient stock allocation. These bottlenecks create a delay in the delivery of the product.

- Supply chain disruptions: The supply can be disrupted by either internal or external issues. Internal issues can be controlled, but external problems like natural disasters and supplier issues cannot be forecasted or solved easily.

- Outdated technology: If the system is not up to date, it can create a disadvantage among competitors. Also, such systems often break down and cause delays.

- Shipping service partner: Partnering with service providers with no reputation or experience can often get you into trouble. Such firms can cause delays, missing packages, and damage to the couriers.

6 Proven Ways to Improve Your DIFOT Score

- Optimize the warehouse: Streamline the operations of the warehouse logistics, such as picking, packing, and dispatch. Use warehouse management software for assistance.

- Calculate accurate ETA: Utilise data analytics to accurately predict the ETA based on past data and current performance of the supply chain.

- Track the delivery routes: Implement real-time tracking to reduce human errors and avoid other unexpected delays, such as traffic blocks.

- Integrating with other business systems: Connect your logistics, inventory, and sales using ERP platforms for better coordination. This brings visibility and reduces delays.

- Strong inventory policy: Implement policies that cover stock level audits, reorder point setting, and forecast demand. An effective system helps in automating many processes.

- Partner with a reputable freight forwarder: Partner with a reputable logistics firm with a proven track record of on-time deliveries. A strong logistics partner can provide customs clearance and ensure your goods reach their destination as planned.

How DTDC Australia Helps Improve Your DIFOT Score

DTDC Australia is a reputable freight forwarding company with a network all over Australia and expertise in customs clearance. Equipped with the latest technology, we offer services specifically designed for small businesses to elevate their supply chain.

DTDC Australia Services

Our exclusive services can significantly improve your DIFOT score and help achieve customer satisfaction. To know more about improving your DIFOT score, talk to our expert team.

Leveraging Technology to Boost DIFOT

The emergence of AI and data analytics has already brought drastic changes in industries like e-commerce. With assistance from these technologies, you can even target a DIFOT score of 100%.

Build systems that can help you leverage these technologies and also keep them up to date. However, we recognize that not everyone can afford these, so businesses should consider partnering with a logistics service provider that offers the latest technology resources.

Frequently Asked Questions (FAQs)

What does DIFOT mean?

DIFOT is the short form of ‘Delivery in Full, On Time’, and it’s a metric used to measure the ratio of orders that are delivered completely and on time.

How do you calculate DIFOT?

DIFOT can be calculated by dividing the number of orders delivered in full and on time by the total number of orders and then multiplying by 100.

What is the difference between OTIF and DIFOT?

OTIF is the abbreviation of ‘On Time In Full’. Both OTIF and DIFOT mean the same performance matrix, and they are used interchangeably.

What is a good DIFOT score?

A good DIFOT score ranges from 95% to 98%. Even 100% is achievable with the help of proper systems.